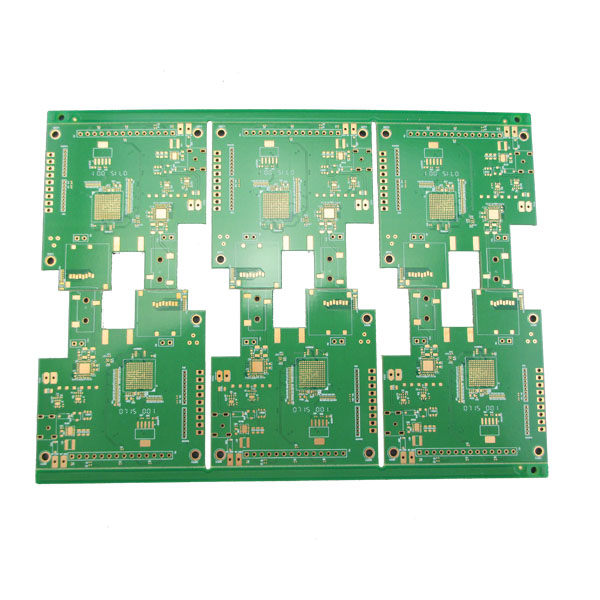

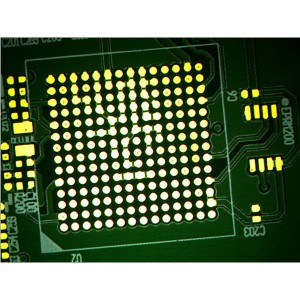

4 ungqimba wesifunda ibhodi ixhunywe nge-solder mask

Imininingwane Yomkhiqizo

| Izinhla | 4 izingqimba |

| Ukujiya kwebhodi | 1.60MM |

| Izinto | I-FR4 tg150 |

| Ubukhulu bethusi | I-1 OZ (35um) |

| Ukuqedelwa Kwaphezulu | ENIG Au Ubukhulu 0.05um; Ni Ubukhulu 3um |

| I-Min Hole (mm) | I-0.203mm ixhunywe ngesifihla se-solder |

| Min Line Ububanzi (mm) | 0.15mm |

| I-Min Line Space (mm) | 0.20mm |

| Isifihla Solder | Okuluhlaza okotshani |

| Umbala Wezinganekwane | Mhlophe |

| Ukucubungula ngomshini | V-amagoli, CNC Milling (umzila) |

| Ukupakisha | Isikhwama se-anti-static |

| Ukuhlolwa kwe-E | Uphenyo lokundiza noma i-Fixture |

| Izinga lokwamukelwa | IPC-A-600H Isigaba 2 |

| Isicelo | Izithuthi zikagesi |

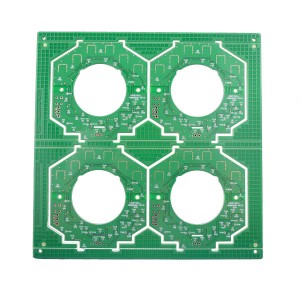

Imultilayer

Kulesi sigaba, singathanda ukukunikeza imininingwane eyisisekelo mayelana nezinketho zesakhiwo, ukubekezelelana, izinto zokwakha, nemihlahlandlela yokuhlelwa kwamabhodi ama-multilayer. Lokhu kufanele kwenze impilo yakho ibe lula njengonjiniyela futhi kukusize ukuklama amabhodi wakho wesifunda aphrintiwe ukuze alungiselelwe ukukhiqizwa ngezindleko eziphansi kakhulu.

Imininingwane ejwayelekile

| Okujwayelekile | Okukhethekile ** | |

| Usayizi wesifunda omkhulu | 508mm X 610mm (20 ″ X 24 ″) | --- |

| Inani lezendlalelo | izingqimba ezingama-28 | Ngesicelo |

| Ukucindezela okukhulu | 0.4 mm - 4.0mm | Ngesicelo |

Izinto ze-PCB

Njengomhlinzeki wobuchwepheshe obuhlukahlukene be-PCB, amavolumu, izinketho zesikhathi sokuhola, sinokukhethwa kwezinto ezijwayelekile lapho umkhawulo womkhawulokudonsa omkhulu wezinhlobo ezahlukahlukene ze-PCB ungambozwa futhi ohlale utholakala endlini.

Izidingo zokunye noma okokusebenza okukhethekile nazo kungahlangatshezwana nazo ezimweni eziningi, kepha, ngokuya ngezidingo eziqondile, kungadingeka izinsuku ezi-10 zokusebenza ukuze kutholwe lokho okubhaliwe.

Thintana nathi futhi uxoxe ngezidingo zakho nomunye wokuthengisa kwethu noma iqembu le-CAM.

Izinto ezijwayelekile ezigcinwe esitokweni:

| Izingxenye | Ubukhulu | Ukubekezelelana | Uhlobo lwe-Weave |

| Izendlalelo zangaphakathi | 0,05mm | +/- 10% | 106 |

| Izendlalelo zangaphakathi | 0.10mm | +/- 10% | 2116 |

| Izendlalelo zangaphakathi | 0,13mm | +/- 10% | 1504 |

| Izendlalelo zangaphakathi | 0,15mm | +/- 10% | 1501 |

| Izendlalelo zangaphakathi | 0.20mm | +/- 10% | 7628 |

| Izendlalelo zangaphakathi | 0,25mm | +/- 10% | 2 x 1504 |

| Izendlalelo zangaphakathi | 0.30mm | +/- 10% | 2 x 1501 |

| Izendlalelo zangaphakathi | 0.36mm | +/- 10% | 2 x 7628 |

| Izendlalelo zangaphakathi | 0,41mm | +/- 10% | 2 x 7628 |

| Izendlalelo zangaphakathi | 0,51mm | +/- 10% | 3 x 7628/2116 |

| Izendlalelo zangaphakathi | 0,61mm | +/- 10% | 3 x 7628 |

| Izendlalelo zangaphakathi | 0.71mm | +/- 10% | 4 x 7628 |

| Izendlalelo zangaphakathi | 0,80mm | +/- 10% | 4 x 7628/1080 |

| Izendlalelo zangaphakathi | 1,0mm | +/- 10% | 5 x7628 / 2116 |

| Izendlalelo zangaphakathi | 1,2mm | +/- 10% | 6 x7628 / 2116 |

| Izendlalelo zangaphakathi | 1,55mm | +/- 10% | 8 x7628 |

| Ukulungiselela | 0.058mm * | Kuya ngesakhiwo | 106 |

| Ukulungiselela | 0.084mm * | Kuya ngesakhiwo | 1080 |

| Ukulungiselela | I-0.112mm * | Kuya ngesakhiwo | 2116 |

| Ukulungiselela | 0.205mm * | Kuya ngesakhiwo | 7628 |

Ubukhulu beCu bezingqimba zangaphakathi: Okujwayelekile - 18µm no-35 µm,

ngesicelo 70 µm, 105µm no 140µm

Uhlobo lwento: FR4

I-Tg: cishe. 150 ° C, 170 ° C, 180 ° C

εr ku-1 MHz: ≤5,4 (ejwayelekile: 4,7) Okuningi kutholakala ngokucela

Beka isitaki phezulu

Ukuqoqwa kwe-PCB kuyinto ebalulekile ekutholeni ukusebenza kwe-EMC komkhiqizo. Ukuqoqwa okuhle kungasebenza kakhulu ekwehliseni imisebe evela kuluphu ku-PCB, kanye nezintambo ezixhunywe ebhodini.

Izici ezine zibalulekile maqondana nokucatshangelwa kokuqoqwa kwamabhodi:

1. Inani lezendlalelo,

2. Inombolo nezinhlobo zezindiza (amandla kanye / noma umhlaba) ezisetshenzisiwe,

3. Ukuhleleka noma ukulandelana kwezendlalelo, futhi

4. Isikhala phakathi kwezendlalelo.

Imvamisa akubhekwa kangako ngaphandle kwenani lezendlalelo. Ezimweni eziningi ezinye izici ezintathu zibaluleke ngokulinganayo. Lapho unquma ngenani lezendlalelo, okulandelayo kufanele kubhekwe:

1. Inani lezimpawu ezizohanjiswa nezindleko,

2. Imvamisa

3. Ngabe umkhiqizo kuzofanele uhlangabezane nezidingo zokuphuma zeClass A noma ze-Class B?

Imvamisa kubhekwa kuphela into yokuqala. Empeleni zonke izinto zibaluleke kakhulu futhi kufanele zibhekwe ngokulinganayo. Uma idizayini enkulu izotholakala ngesilinganiso esiphansi sesikhathi nangezindleko eziphansi kakhulu, into yokugcina ingabaluleka kakhulu futhi akufanele inganakwa.

Isigaba esingenhla akufanele sithathwe njengesisho ukuthi awukwazi ukwenza ukwakheka okuhle kwe-EMC ebhodini lezingqimba ezine noma eziyisithupha, ngoba uyakwazi. Kukhombisa kuphela ukuthi zonke izinhloso azinakufezwa ngasikhathi sinye futhi ukuhlehla okuthile kuzodingeka. Njengoba zonke izinhloso ezifunwayo ze-EMC zingahlangatshezwa ngebhodi elinezingqimba eziyisishiyagalombili, asikho isizathu sokusebenzisa izingqimba ezingaphezu kweziyisishiyagalombili ngaphandle kokufaka izingqimba zomzila wesiginali ezingeziwe.

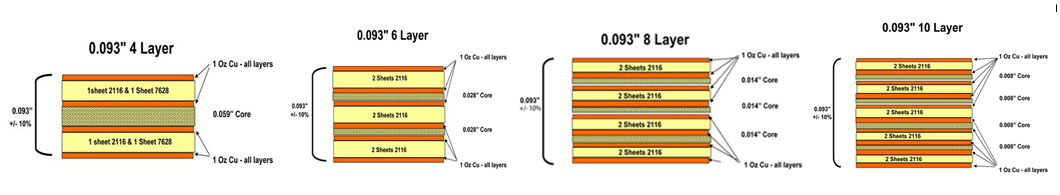

Ukujiya okujwayelekile kokuhlanganiswa kwama-PCB amaningi kungu-1.55mm. Nazi ezinye izibonelo ze-multilayer PCB stack up.

Insimbi Okuyinhloko I-PCB

Ibhodi Yesekethe Eliphrintiwe Lensimbi (i-MCPCB), noma i-PCB eshisayo, luhlobo lwe-PCB olunempahla yensimbi njengesisekelo salo sokusabalalisa ukushisa kwebhodi. Inhloso yengqikithi ye-MCPCB ukuqondisa kabusha ukushisa kude nezakhi zebhodi ezibucayi nezindawo ezingabalulekile kangako njengokusekelwa nge-heatsink yensimbi noma umnyombo wensimbi. Izinsimbi eziyisisekelo ku-MCPCB zisetshenziswa njengenye indlela yamabhodi we-FR4 noma we-CEM3.

Metal Core PCB Izinto kanye Ubukhulu

Ingqikithi yensimbi ye-PCB eshisayo ingaba yi-aluminium (i-aluminium core PCB), ithusi (i-PCB eyinhloko yethusi noma i-PCB yethusi esindayo) noma ingxube yama-alloys akhethekile. Okuvame kakhulu yi-PCB esemqoka ye-aluminium.

Ubukhulu bezinsimbi zensimbi kumacwecwe esisekelo se-PCB imvamisa kungama-30 mil - 125 mil, kepha amapuleti amakhulu futhi azacile kungenzeka.

Ubukhulu bocingo lwe-MCPCB lungaba yi-1 - 10 oz.

Izinzuzo ze-MCPCB

Ama-MCPCB angaba lusizo ukuwasebenzisela ikhono lawo lokuhlanganisa ungqimba we-dielectric polymer onomswakama ophezulu oshisayo wokumelana nokushisa okuphansi.

I-Metal core PCB idlulisa ukushisa okuphindwe kasishiyagalombili kuye kwayi-9 kunama-PCB e-FR4. I-MCPCB laminates ihlakaza ukushisa, igcina ukupholisa okukhiqiza izinto kupholile okuholela ekwandeni kokusebenza nempilo.