Metal Core PCB \ MCPCB yethusi core PCB

Imininingwane Yomkhiqizo

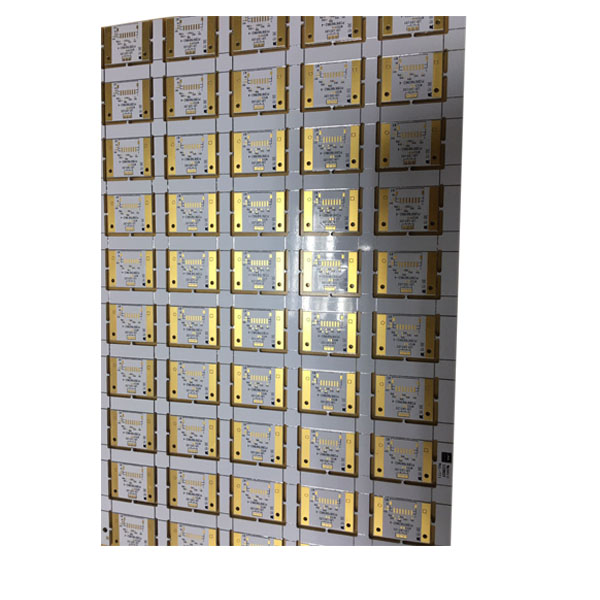

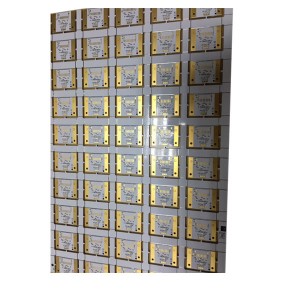

| Izinhla | 2 izingqimba |

| Ukujiya kwebhodi | I-1.6MM |

| Izinto | I-Aluminium |

| Ubukhulu bethusi | I-1 OZ (35um) |

| Ukuqedelwa Kwaphezulu | (ENIG) Igolide lokucwiliswa |

| I-Min Hole (mm) | 0.25mm |

| Min Line Ububanzi (mm) | 0.28mm |

| I-Min Line Space (mm) | 0.20mm |

| Isifihla Solder | Mhlophe |

| Umbala Wezinganekwane | Mnyama |

| Ukupakisha | Isikhwama se-anti-static |

| Ukuhlolwa kwe-E | Uphenyo lokundiza noma i-Fixture |

| Izinga lokwamukelwa | IPC-A-600H Isigaba 2 |

| Isicelo | I-LED |

1. Isingeniso

AmaPandawill Circuits ahlinzeka ngezindleko ezenziwe nge-aluminium kanye nebhodi lesifunda le-FR4 lezinto zokukhanyisa kwe-LED nezicelo zokubonisa ze-LED.

Zisetshenziswa ku:

Ukukhanya komugqa we-strip ukukhanyisa

Ukukhanyisa kwezimoto

Izicelo zasolwandle

Izicelo zokwakha

Izimpawu Zethrafikhi / Zomgwaqo

Amabhodi wamaphuzu / izikrini zevidiyo njll

Ngaphezulu kweminyaka eyi-10 kuma-PCB e-LED, siyakwazi ukunikela ngokukhethwa okuhle kakhulu kwezinto zokwakha, ukuqeda okuthengiswayo kanye nezisindo zethusi ukuhlangabezana nokudlula ukusebenza namazinga wokuthembeka wesikhathi eside adingekayo kubuchwepheshe obusekelwe ku-LED. Indlela kaPandawill ekusetshenzisweni kokukhanyisa kwe-LED igxile kuzo zonke izici zokwakhiwa nokwakhiwa kwebhodi lesifunda.

1. Yiziphi izinto ezisiza ukuhweba ezinikezela ngemininingwane efanayo noma ephakeme ngentengo ephansi?

2. Amabhodi ahlelwe kanjani ukuze enze isivuno esikhulu kunazo zonke kusuka kuphaneli yokukhiqiza?

3. Usetshenziswa kanjani umzila nokufaka amagoli ukufaka amabhodi ngamaphaneli ukuze anikeze ukuqina okukhulu kwephaneli lokukhiqiza nokunciphisa inani lomsebenzi wokuqeda umsebenzi?

Isiphetho se-4.Which sinikeza ukusebenza okuhle kakhulu kwenqubo yakho yomhlangano ophakanyisiwe.

5.Yini isisindo sethusi esifanele esizonikeza ukuthembeka kwesikhathi eside okudingekayo ukufanisa impilo elindelekile yomkhiqizo wokukhanyisa we-LED.

6. Yimuphi umbala, isiphetho (isicwebezelisi noma i-matte) kanye nemininingwane ye-solder resist okufanele isetshenziselwe ukumunca nokusabalalisa inani elikhulu lokukhanya / ukushisa okuphezulu, noma ukugcina ukukhanya komhlophe kukhanye ukukhanya ngempumelelo ngangokunokwenzeka ngaphandle kokushintshwa kombala?

7. Ikhwalithi yesikrini sikasilika nokuqedela ukuze imiyalo yokufaka kanye nokufakwa uphawu komkhiqizo kuvezwe kahle.

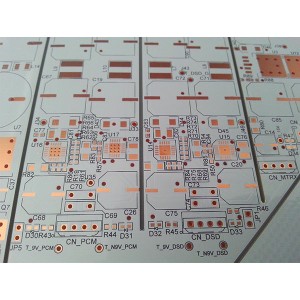

Insimbi Okuyinhloko I-PCB

Ibhodi Yesekethe Eliphrintiwe Lensimbi (i-MCPCB), noma i-PCB eshisayo, luhlobo lwe-PCB olunempahla yensimbi njengesisekelo salo sokusabalalisa ukushisa kwebhodi. Inhloso yengqikithi ye-MCPCB ukuqondisa kabusha ukushisa kude nezakhi zebhodi ezibucayi nezindawo ezingabalulekile kangako njengokusekelwa nge-heatsink yensimbi noma umnyombo wensimbi. Izinsimbi eziyisisekelo ku-MCPCB zisetshenziswa njengenye indlela yamabhodi we-FR4 noma we-CEM3.

Metal Core PCB Izinto kanye Ubukhulu

Ingqikithi yensimbi ye-PCB eshisayo ingaba yi-aluminium (i-aluminium core PCB), ithusi (i-PCB eyinhloko yethusi noma i-PCB yethusi esindayo) noma ingxube yama-alloys akhethekile. Okuvame kakhulu yi-PCB esemqoka ye-aluminium.

Ubukhulu bezinsimbi zensimbi kumacwecwe esisekelo se-PCB imvamisa kungama-30 mil - 125 mil, kepha amapuleti amakhulu futhi azacile kungenzeka.

Ubukhulu bocingo lwe-MCPCB lungaba yi-1 - 10 oz.

Izinzuzo ze-MCPCB

Ama-MCPCB angaba lusizo ukuwasebenzisela ikhono lawo lokuhlanganisa ungqimba we-dielectric polymer onomswakama ophezulu oshisayo wokumelana nokushisa okuphansi.

I-Metal core PCB idlulisa ukushisa okuphindwe kasishiyagalombili kuye kwayi-9 kunama-PCB e-FR4. I-MCPCB laminates ihlakaza ukushisa, igcina ukupholisa okukhiqiza izinto kupholile okuholela ekwandeni kokusebenza nempilo.